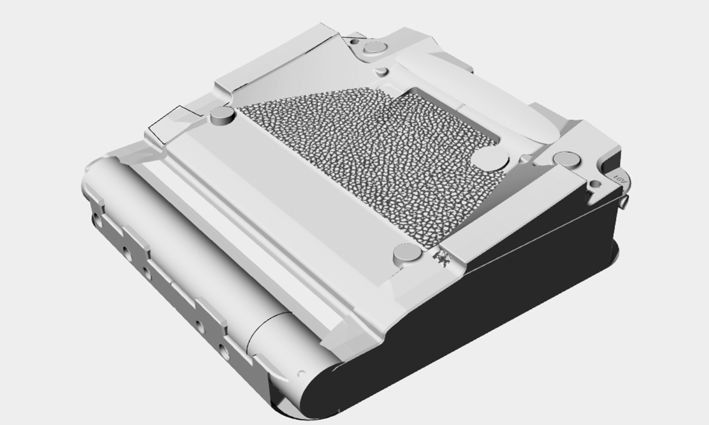

① 1. cavity status, e.g. rust, polish, welding, PL, shut off, slider and etc

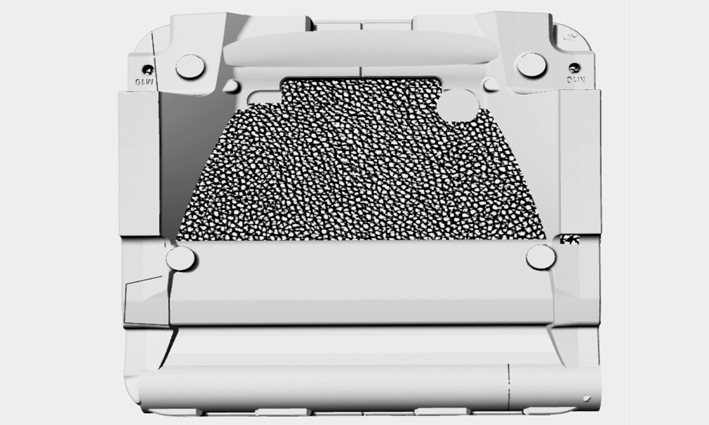

②Consistency between grain mapping parts and actual tool

③ Consistency between actual tool and customer list

④ Cavity status, damage during transportation and etc

① Consistency between actual print and grain on grain instruction sheet and grain mapping

② Completeness of grain print and pattern connection

③ Efficient masking on PL, Shut off and slider line

① Grain depth meets standard process sheet

② Grain appearance meeting standard plaque

③ Smooth transiton between different depths

④ Masking area is complete

① Undercut condition in PL

② Smooth transiton between different depths

③ General grain appearance is ok

④ Grain direction, area and depth meet quality standard.

① Anti-scratch implementation status

② Gloss on tool

③ Rust remavel process and quality signature

④ Packing completency, marking visibility and tool accessories