Reductionof whiting/ghosting etc.

Painted appearance

Heating temperature is low and doesnot damage the steel

Applicable either on running andexisting tools

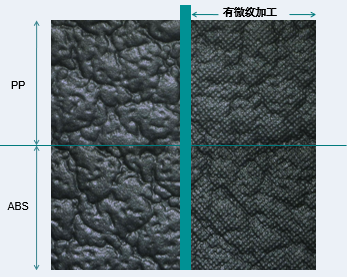

Effectiveto reduce gloss

Improvesscratch-resistance and tactile impression

Processwithout damage on the grain

Peeling-offof Cera-Coat is available for reprocess.

Cera-Coatreduces the parts weight that leads cost-reduction.

Cera-Coathelps correction of deformation when molding.

Cera-Coatis applicable on working moulds.

Cera-Coatprevents gloss variation.

Improvedmethod of gloss reduction

Paintless

Layerthickness up to 20μm

Lowercoating temperature means no thermal impairment of tool steel

Usableon original equipment or for optimization

Suitablefor typical cleaning agents(neutral・slightly acidic)